| NO | EQUIPMENT | PARAMETERS | QTY. | MAIN FUNCTION |

| 1 | CNC Flame Cutting Machine | Plate length: Max 16000mm Plate width: Max 4500mm Plate Thickness: Max 150mm Cutting accuracy: U4 RZ5 3 Material: Carbon steel and low alloy steel | 1 | Plate Cutting |

| 2 | CNC plasma cutting machine | Plate length: Max 16000mm Plate width: Max 4500mm Plate Thickness: Max 50mm Cutting accuracy: U3 RZ5 2 Material: Carbon steel , stainless steel and low alloy steel | 1 | Plate Cutting |

| 3 | Pre-bending machine | Processing diameter: φ400-φ6000mm Equipment pressure: 60000kN Plate Thickness(max): Max150mm Plate Width: Max 4500mm Material: Carbon steel and low alloy steel | 1 | Pre-bending |

| 4 | Rolling machine | Processing diameter: Max 6000mm Plate Thickness: Max 150mm Pipe length: Max 3200mm Material: Carbon steel and low alloy steel | 1 | Forming |

| 5 | Rolling machine | Processing diameter: Max 6000mm Plate Thickness: Max 100mm Pipe length: Max 4000mm Material: Carbon steel and low alloy steel | 1 | Forming |

| 6 | Crane | QD20/5-22.5A5/QD20/5-16.5A5/QD20/5-31.5A5/QD32/5-22.5A5 | 8 |

(OD 36"~300", 4M)

1. cutting groove

2. pre-bending

3. rolling up

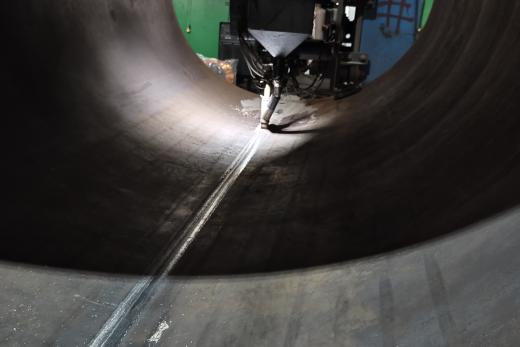

4. internal welding

5. outside welding

6. re-rolling

7. NDT for straight seams

8. Steel pipe docking

9. girth welding

10. circular seam NDT

11. Final Ispection

12. Final Ispection

13. Final Ispection

Your email address will not be published. Required fields are marked *